Jctprint Machinery Co., Ltd

Air shaft is widely used in printing, packaging, plastic, paper making, spinning industries for all the machines with the winding, rewinding unit and slitting unit for the operation of material in roll.

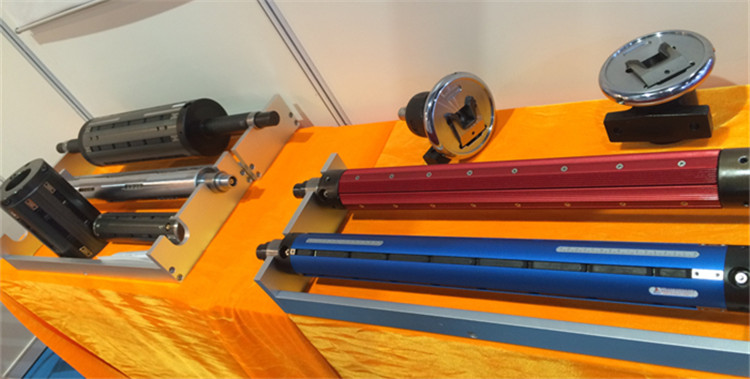

1.5 Inch Steel or Customized Aluminum Precision Air Expanding Shaft Supply for Reeling

Application

Air shaft application in all industries :

Air shaft for printing industry : Flexo printing machine,Offset printing machine, Gravure printing machine

Air shaft for cutting industry : Cutting machine

Air shaft for slitting industry : Slitting machine

Air shaft for coating industry : Coating machine

Air shaft for laminating industry : Laminating machine

Air shaft for bag making industry : Bag making machine

Classification

1. According to the structure

The shaft can be divided into key type air shaft and lath type air shaft. Most are using the key type air shaft and lath type air shaft is usually used on rewinding part of slitting machine or thin paper core. Because thin paper core is easy to be out of shape.

The key type air shaft is possible to make the paper core broken.

The tile type air shaft is three pieces of tiles after inflation. The roundness is good.

But compared with key type air shaft, the strength and load is smaller and the price is higher. So most customer will choose key type air shaft. We need to choose suitable not expensive product.

2. According to the diameter

We have the following normal type but other dimensions can be customized.

Type | Unaerated diameter(Ø mm) | Inflated diameter (Ø mm) | Applicable volume tube inner diameter (Ø mm) |

1" | 24.8 | 24.8-28 | 25-26 |

1.5" | 37 | 40-42 | 38-38.5 |

2" | 49 | 52-54 | 50-51 |

3" | 74-75 | 80-82 | 75.5-78 |

4" | 99-100 | 104-106 | 101-102 |

5" | 125 | 130-133 | 126-128 |

6" | 150 | 154-156 | 151-153 |

8" | 200 | 206-264 | 202-204 |

10" | 250 | 260-264 | 252-256 |

12" | 300 | 308-310 | 302-305 |

Feature of our product :

1). Inflatable operation time is short

Our product just needs 3 seconds to finish expansion of the shaft and separation with paper tube to complete the inflatable and deflated, without necessary to rework any side of the shaft end to reach tight holding on with the paper tube.

2). Paper tube placed simple

To inflatable and deflated action, movable and fixed in any position on the paper tube.

3). Heavy loading

The diameter of the shaft can be decided according to the actual needs of customers and we use high-strength steel to increase the carrying weight to meet all the customer’s request.

4). High economic efficiency

The design of the shaft is a special function, all kinds of thick, thin, wide, narrow paper tube can all be applied.

Advantage

Now I will introduce the advantages of our air shafts :

A: Air shaft body Material

We adopt hi-precision cold-drawn steel tube as the shaft body . The thickness of this kind of tube is uniform so after inflation , all key strips will stick out at the same height which will realize minimum eccentricity of the paper core.

And it will greatly weaken centrifugal force of the whole air shaft when it is rotating and will keep a dynamic balance.This kind of material is 460 dollars more expensive per ton than normal materials.

B: Key bar structure for our key type air shaft

Our exported key type is the following structure, it used the whole long key bar forming a good protective ring around the air chamber ,and we adopt the pagoda springs. It can bear 300000 compression without broken and the quality guarantee period is one year.

The key bar is made of aluminum alloy. It is light in weight and is suitable for ordinary tubes such as paper tubes.

As shown in the following figure:

C. From the analysis of future maintenance costs

Those two structures of the expansion shaft, if need to repair ,you must replace all the keys, springs and air bags, but our structure is different. Even if need to repair after a few years later, because the spring can be directly take away, for dozens of springs, the cost of a few dollars. Plus a new airbag, the general maintenance and cost, one meter about at 24 dollars, plus a labor costs, even if a two-meter shaft, all the maintenance costs are around 63 dollars.

Quality control

We have the quality control system during the whole production from the very beginning to the end and our principle is to make sure each shaft is qualified.

Company

FAQ

1. How should I place the order?

For air shaft , please send us your drawing, or let us know your request.

2. What is your MOQ?

1 Piece.

3. What material of your shaft is made of?

45# steel ,aluminum.

4. Can you produce relative product,like adapter,hand shank?

Yes,Sure.

Contact us

For more information of our product, please get in touch with us directly to :

Ms. Vicky (EXP. MANAGER)