Jctprint Machinery Co., Ltd

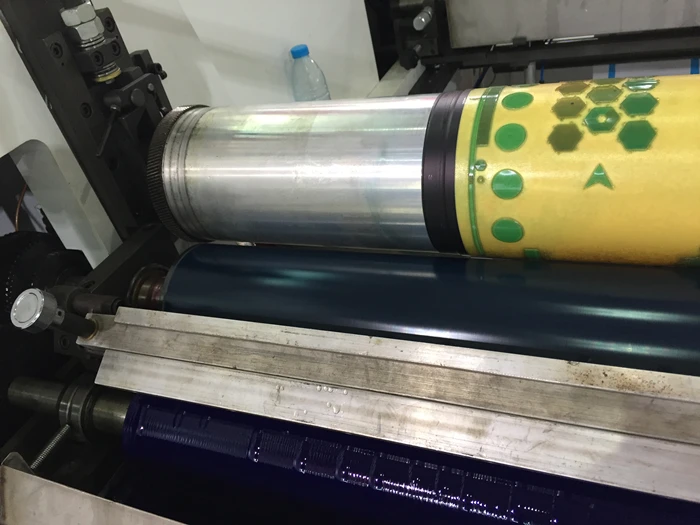

Steel flexo print cylinder for flexo printing machine

Flexo printing cylinders can be used on most of letterpress, stacked flexo machine,satellite flexo machine,unit flexo machine and combination presses.

A.Circumference of Printing Cylinder: 100-1500mm

B.There are lines on the cylinder which can make sure the printing plate on right place

C.Precision on the cylinder production

You can find that during the production process we always put precision as the most important thing.

We lathe twice and we make the mechanical calibration twice.This is because precision will affect the printing result. For example, sometimes you find the inner diameter and the outer diameter are both correct according to the drawing but when you are using the cylinders on the flexo printing machine there is on problem of non- evenly distribution of the inks on the printing material. This is because of the concentricity. Our production technique can perfectly solve this problem and we will control the concentricity to be 0-15microns.

Advantage

A. High-quality materials for base roller

We adopt 45# seamless steel tube or No5 series aluminum as the base roller,which have enough stiffness to make sure the bending deflection is not over the allowable value under heavy pressure.

B. Dynamic balance test twice

We will do dynamic balance test twice on each cylinders,the radial jumped error will be less than±0.005,which will help do evenly distribution of the inks on the printing material.

C.Advanced welding technology

Adopt CO2 protective welding orTIG welding technology at the head of the roller,will assure the welding is continuous and smooth.

D. Heating treatment process

This process will increased hardness and to prevent the cylinder from deformation and will assure the geometric accuracy and long service life.

Betty Peng

Jinan Jinchangtai Industry And Trade Co., Ltd

Mobile/wechat/Whatsapp/skype: 0086-13065059356

Email: [email protected],[email protected]

Website: www.jctprinting.com/