Jctprint Machinery Co., Ltd

This series punching machine is mainly product of our company. It is Suitable for the production of labels, playing cards, aluminum plastic, PP ,PE-foil, self-adhesive foil, envelopes of any design or size.with an average production of about 900.000 production of high precision hourly.

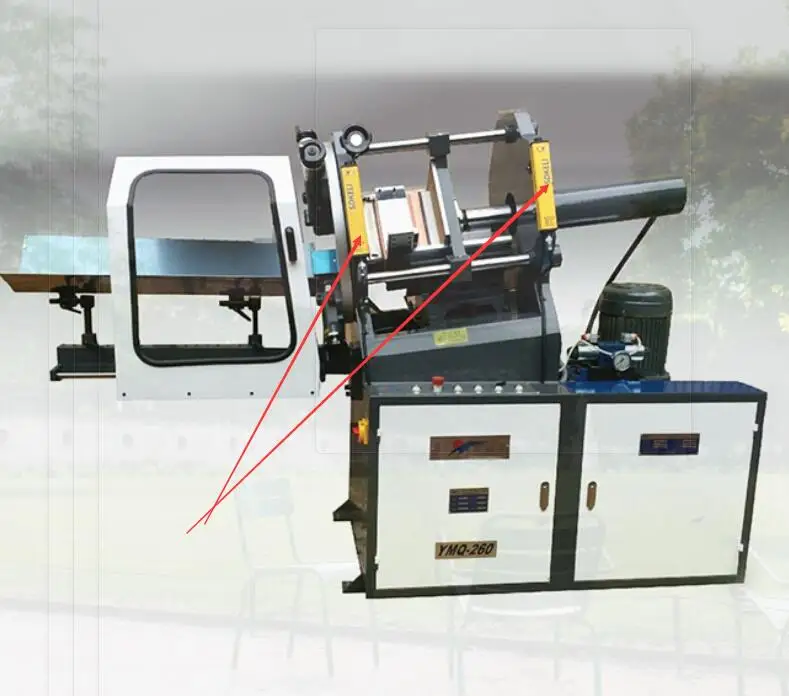

YMQ series label Die Cutting/Punching machine :

This series punching machine is mainly product of our company. It is Suitable for the production of labels, playing cards, aluminum plastic, PP ,PE-foil, self-adhesive foil, envelopes of any design or size.with an average production of about 900.000 production of high precision hourly.

This machine adopts hydraulic pressure system with a push-cubeself-adjusting to every position of the"V"hold where the pack is positioned. The working table has a photoelectric cell which gives maximum safety to the operator and allows a quick change of the following punch and is adaptable both for low and medium production.

The working process is completely stability.The die cutting products surface is smooth, and the size is unified and regular with high precision.

Main parameters:

|

Model |

YMQ-115 |

YMQ-115-1 |

YMQ-200 |

YMQ-260 |

YMQ-350 |

|

Max. Die-cut size |

140*140mm |

140*140mm |

220*220mm |

300*240mm |

380*300mm |

|

Min. Die-cut size |

20*20mm |

20*20mm |

50*50mm |

65*65mm |

90*90mm |

|

Max. Die-cut height |

200mm |

200mm |

220mm |

260mm |

310mm |

|

Working speed |

12Time/min |

12Time/min |

10Time/min |

8Time/min |

7Time/min |

|

Die-cut pressure |

3T |

3T |

5T |

8T |

11T |

|

Dimension(L*W*H) |

1350*750*1500 |

1400*850*1500 |

2200*850*1650 |

2450*1000*1800 |

2600*1250*1900 |

|

Gross Weight |

680kg |

660kg |

1200kg |

1600kg |

1900kg |

|

Special configuration |

/ |

Photo electric protection |

|||

Features of our die cutting machine:

1. Widely use: It is Suitable for the production of labels, playing cards, aluminum plastic, New year card, notebook, envelopes of any design or size.

2. High efficiency: with an average production of about 900.000 production of high precision hourly.

3. This machine adopts hydraulic pressure system.

4. With a push-cube self-adjusting to every position of the "V" hold where the pack is positioned

5. The working table has a photoelectric cell which gives maximum safety to the operator and allows

6. The working process stability, products surface is smooth, and the size is unified and regular with high precision

|

1. Photoelectric protection device : The Photoelectric protection device is changed from ordinary photoelectric eye to grating, which is safer to use.

|

2. Material receiving rack: The Material receiving rack is changed to a separate receiving rack, and the shape of the tool changes, which will not affect the receiving processing. |

|

|

|

3. Tool holder: The tool holder is changed to the fine-turning positioning of the overall tool holder. There are five independent tool holders.

|

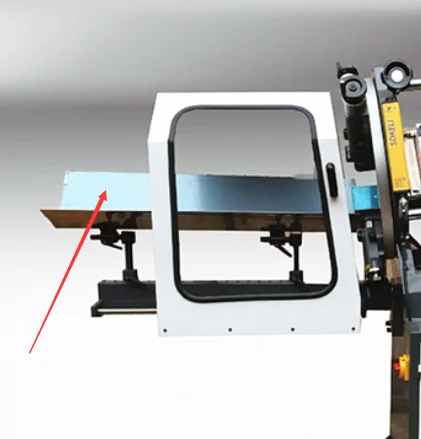

4. Operating station: The operation of the discharge platform is larger, the material turnover can be placed directly, and the discharging operation is more convenient. |

|

|

|

5. Push-cut board: The push-cut board is changed to a collective three-point support without displacement push plate, no matter the material size. it will not affect the direction of the push plate |

6. Oil pump motor: The ordinary motor is changed to a special oil pump motor to make the power transmission more complete and quieter. |

|

|

|

7. Electrical configuration: Switch to a more secure electrical contiguration to make sure your safety. |

|

|

|

Q1:We are interested in the die cutting machine,Could you quote the latest price to us?

A1: In order to recommend the suitable machine for you ,please provide following information before we quote price:

1.What material do you want to die cut?

2.What's the max.die cutting size?

3.What's the paper weight? Where will you use it?

Q2: What's the MOQ, Delivery time, and payment terms?

A2: 1. MOQ: 1 set.

2. Delivery time: 30 workdays after receiving T/T 30% payment deposit.

3. Payment Term: T/T 30% as deposit, T/T 70% before shipment or L/C at sight.